Amazing advantages

With EnviroZink ® you will do great!

Safe protection

EnviroZink Hot-Dip Galvanised parts will have a thick layer of Zink coating.

Really safe protection.

Last forever

EnviroZink Hot-Dip Galvanised parts will last more than 35 Years without further treatment.

Really a long time.

Saves the environement

EnviroZink Hot-Dip galvanised parts have the lowest impact to environement compared with other coatings.

Really Good for the environment.

Great Value for money

No doubt: Corrosion protection by Hot-Dip Galvanising is by far the most cost effective way, Call us for more info.

fully recyclable

Zinc is a natural element which is not harmful, can be recycled like steel to 100%.

no more painting

Tired of the yearly coating of your fence, which cost not only a hugh time but also a lot money for the paint? Then you know what we are talking about..

EnviroZink ®

lasts for decades

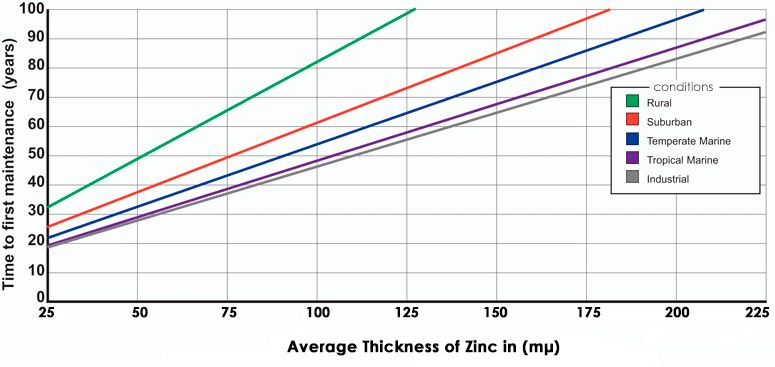

The zinc coating naturally develops an impervious layer of corrosion products on the surface, know as the zinc patina.

The patina, cathodic protection, complete coverage and all of these other features, provide hot-dip galvanized steel with a long, maintenance-free service life. The time to first maintenance for hot-dip galvanized steel can be seen in diagramm here.

With a coating of e.g. 60 micron you can reach over 30 years without any needed treatment for corrosion protection.

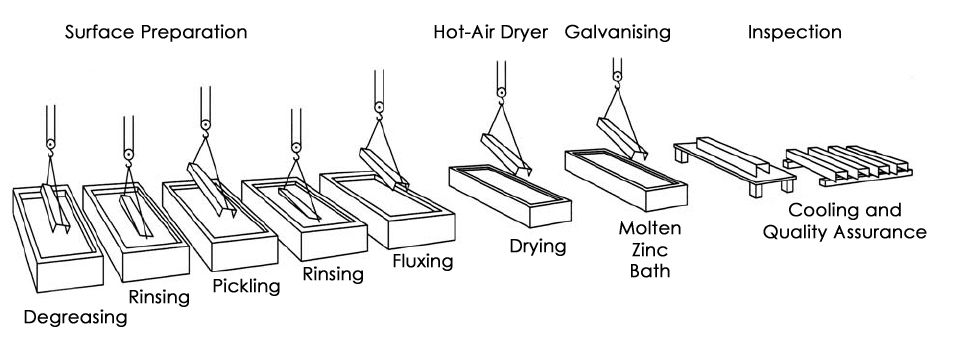

What is Hot-Dip Galvanising?

Hot-dip galvanising is a metallurgical bond between steel and molten zinc, produced in specific installations and under controlled conditions. The process of molecular bonding between two metals is unique and simple, yet provides excellent molecular bonding and cathodic protection.

Pre-galvanising inspection of materials

We will begin by inspecting all received material in order to make sure that the steel can be galvanised according to specifications and to determine if:

1. Design, welds, fabrication methods and general surface conditions are allowing for regular HDG-steps and process;

2. There is paint or any other contaminant (varnish, lacquer, etc.) that requires additional steps, such as cleaning by sandblasting or chemical treatment;

3. Steel assemblies require extra draining and venting holes;

4. There is indication of other elements potentially affecting the normal galvanisation process.

Cleaning and oil removal

The steel is then processed for surface preparation:

1. Grease, oil, markings and dirt removal in a degreasing solution.

2. Pickling hydrochloric or sulfuric acid solutions remove all traces of surface rust and mill scale.

Fluxing

When the steel is thoroughly cleansed, it is then immersed in a liquid flux - ammonium chloride solution - that will protect and prevent oxidation prior to dipping in the molten zinc bath. It will also promote the steel's adhesive properties.

Galvanising

1. Once surface preparation is complete, the steel is immersed in a bath of molten zinc at between 440-460°C. During this step, the zinc metalurgicaly bonds to the steel, creating a series of highly abrasion-resistant zinc-iron alloy layers, commonly topped by a layer of impact-resistant pure zinc.

2. This step requires very little time and the zinc alloy layers are created when the steel reaches the temperature of the molten zinc. Once the layers are formed, the material is slowly withdrawn from the kettle, which usually provides a smooth and uniform surface.

Cooling and quenching

1. Upon exiting the zinc kettle, excess zinc is removed by draining and cooled by dipping in water (commonly called quenching), allowing quick handling.

2. Other cooling solutions exist - they contain other substances allowing for partial passivation of surfaces, which in turn prevent staining and premature oxidation. In the case of reinforcing steel (or rebar), it is preferable to use a chromate solution: this substance promotes compatibility with various concrete compounds.

3. In some cases, quenching might not be recommended because of design considerations or because of the product's end-use. Air-cooling is then recommended. Circumstances and practices can include distortion prevention and painting after galvanising.

Final inspection

Surface condition and coating thickness inspections complete the process. They will ensure that the galvanising meets international hot-dip galvanising standards. A certificate of conformity is available upon request.

Please note that, to maintain our process' efficiency and optimal performance, we regularly inspect all process solutions and equipment, as well as our procedures and measuring (and verification) equipment.